Best Practices for Making Sure Safe and Extensive Lead Offense Abatement

Attending to lead offense abatement calls for a multi-faceted technique to ensure both safety and security and conformity. It's the last clearance procedure, including detailed assessments and laboratory screening, that absolutely confirms a lead-free environment, guaranteeing long-term safety. Exactly how do these practices adjoin to assure detailed lead reduction?

Preliminary Evaluation

Conducting a first assessment is a vital initial step in lead offense abatement. This stage incorporates a detailed evaluation of the property to identify the visibility, level, and particular locations of lead-based threats. Qualified professionals, such as certified lead inspectors or take the chance of assessors, ought to do a thorough site examination, utilizing devices like X-ray fluorescence (XRF) analyzers to precisely identify and determine lead focus in paint, dirt, soil, and water.

The analysis should additionally include a testimonial of the building's background, previous records, and any kind of grievances or wellness issues reported by passengers - Lead Removal Contractors. Recording the searchings for meticulously is essential, as these records create the basis for developing an efficient reduction approach. A complete evaluation additionally entails tasting and research laboratory evaluation, which are important to confirm the visibility of lead and overview succeeding activities

Furthermore, it is imperative to communicate the outcomes transparently to all stakeholders, consisting of building proprietors, occupants, and regulatory authorities. By making sure that the first assessment is performed with precision and rigor, specialists can lay a solid foundation for a targeted and reliable lead abatement procedure, ultimately protecting public health and making sure compliance with regulatory standards.

Appropriate Control

Proper containment is critical to avoid the spread of lead contaminants throughout reduction tasks. Properly taking care of control lessens the risk of lead dirt and debris migrating to non-work areas, thereby safeguarding both the atmosphere and individuals outside the prompt work zone. To achieve proper containment, an airtight barrier of plastic bed linen must be established around the workplace, making certain all seams and edges are securely secured. Lead Removal Contractors. This obstacle ought to extend from flooring to ceiling and be taped to prevent any kind of leaks.

Routine inspections of the control area are needed to look for breaches or weak points in the barrier. Any kind of identified concerns ought to be without delay addressed to keep the integrity of the containment. By sticking to these methods, abatement projects can properly manage lead contamination and minimize involved wellness dangers.

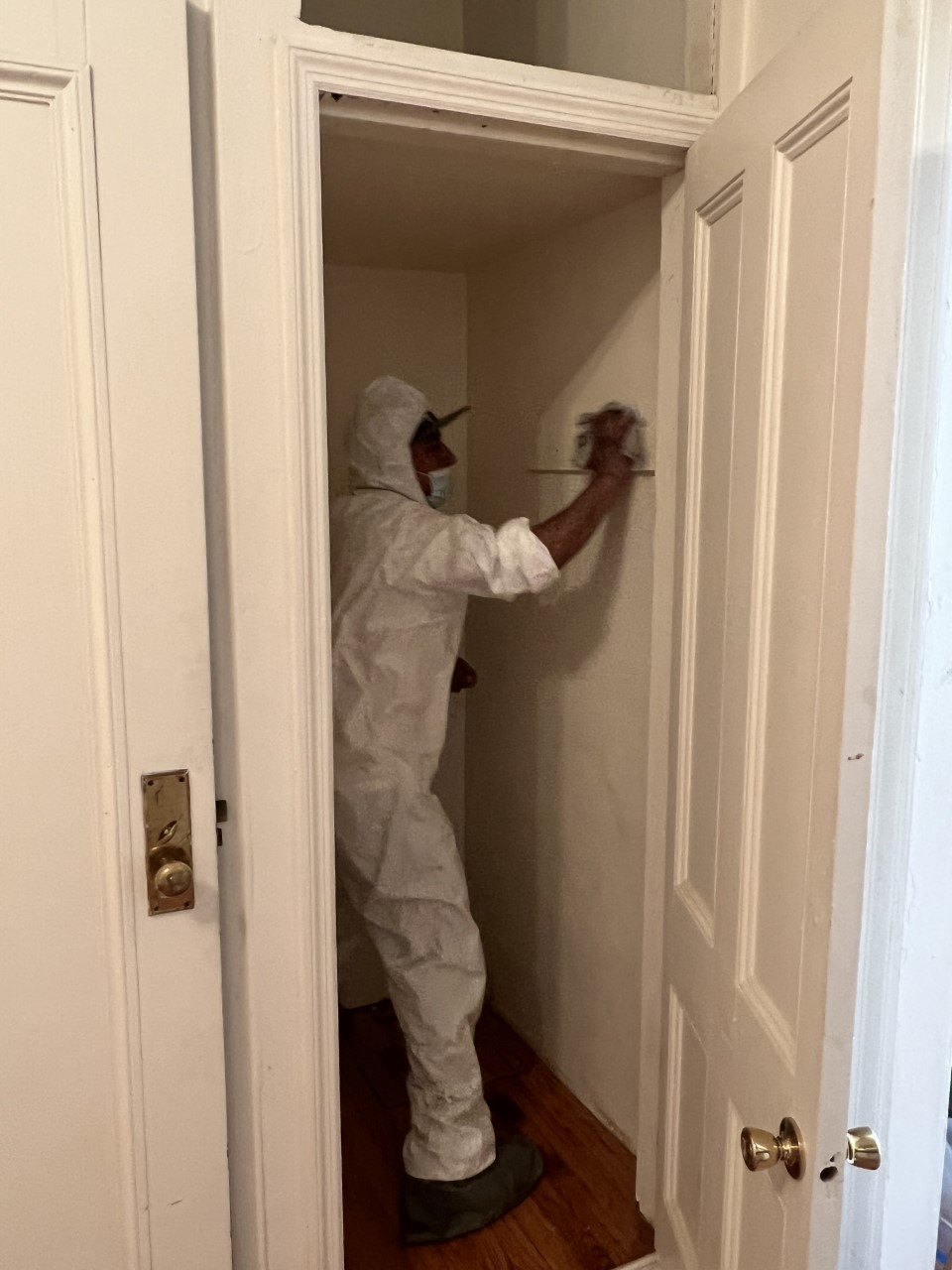

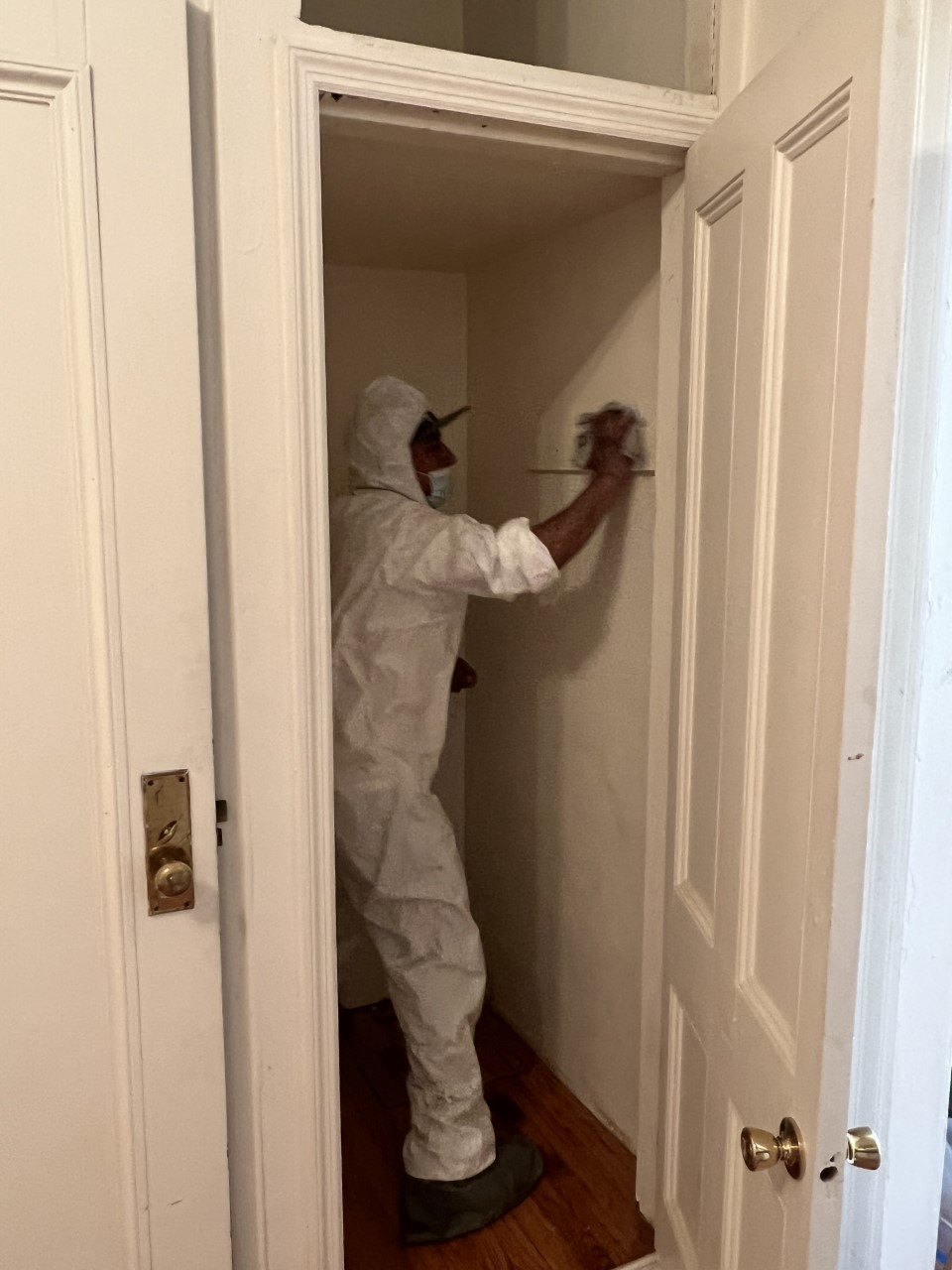

Employee Protection

Making certain worker security is extremely important throughout lead abatement tasks to avoid job-related exposure to unsafe lead particles. Necessary measures include the usage of individual protective devices (PPE) such as respirators, handwear covers, and full-body matches particularly designed to block lead dirt and fumes. Employees need to undergo extensive training on the right use and upkeep of PPE, including fit testing for respirators to make sure optimum efficiency.

Design controls, such as local exhaust ventilation systems, are important in lessening air-borne lead focus in the work setting. Management controls need to also be executed, including limiting the duration of exposure and rotating workers to decrease private exposure times. Routine medical monitoring and read biological monitoring are vital for very early discovery of lead absorption, allowing timely intervention and therapy.

Moreover, establishing a purification protocol is important. Workers should comply with rigid decontamination procedures before breaks and at the end of their change to prevent lead dirt from being lugged outside the workspace. This includes extensive hand and face washing with lead-specific cleaner and altering out of polluted clothes.

Meticulous Clean-up

Keeping a safe workplace expands beyond worker defense and includes precise cleanup to make certain lead bits are thoroughly gotten rid of from the site. The process of thorough cleanup is crucial in stopping the recontamination of the eased off area and securing both present and future residents.

To achieve a thorough clean-up, all job areas must be methodically sanitized. This entails using specialized HEPA (High-Efficiency Particulate Air) vacuum cleaners and wet-wiping techniques to record and eliminate great lead dust that might have picked surface areas. It is essential to clean up all straight surface areas, including floorings, window sills, and kitchen counters, as well as upright surfaces that may have entraped lead particles.

Workers should wear suitable individual protective devices (PPE) during cleaning to avoid direct exposure to recurring lead dust. Utilized cleansing products such as wipes, sponges, and wipe heads must be gotten rid of in conformity with contaminated materials disposal laws.

Final Clearance

Final clearance is the essential concluding stage of lead reduction that establishes whether the website is secure for reoccupation. This vital step includes comprehensive inspection and testing to validate that all lead threats have actually been properly removed.

Final clearance testing not just shields future passengers yet likewise ensures conformity with local, state, and government laws. In addition, it works as a documented recognition of the abatement contractor's adherence to sector best practices. Making certain a thorough and successful last clearance is vital in safeguarding public wellness and fostering count on the abatement procedure.

Conclusion

Making certain risk-free and thorough lead infraction reduction necessitates a complex technique encompassing preliminary assessments with sophisticated discovery methods, efficient containment helpful site approaches, strict employee protection procedures, and precise cleanup treatments. The last clearance phase, featuring thorough inspections and lab check my source screening, is essential to verify conformity with EPA standards. Adherence to these finest techniques guarantees a risk-free setting for owners, reduces health and wellness threats, and upholds regulatory demands, consequently promoting public health and wellness and safety and security in lead-affected areas.

Comments on “Expert Lead Violation Removal in NYC-- Safeguard Against Health Hazards”